What is a floor scale?

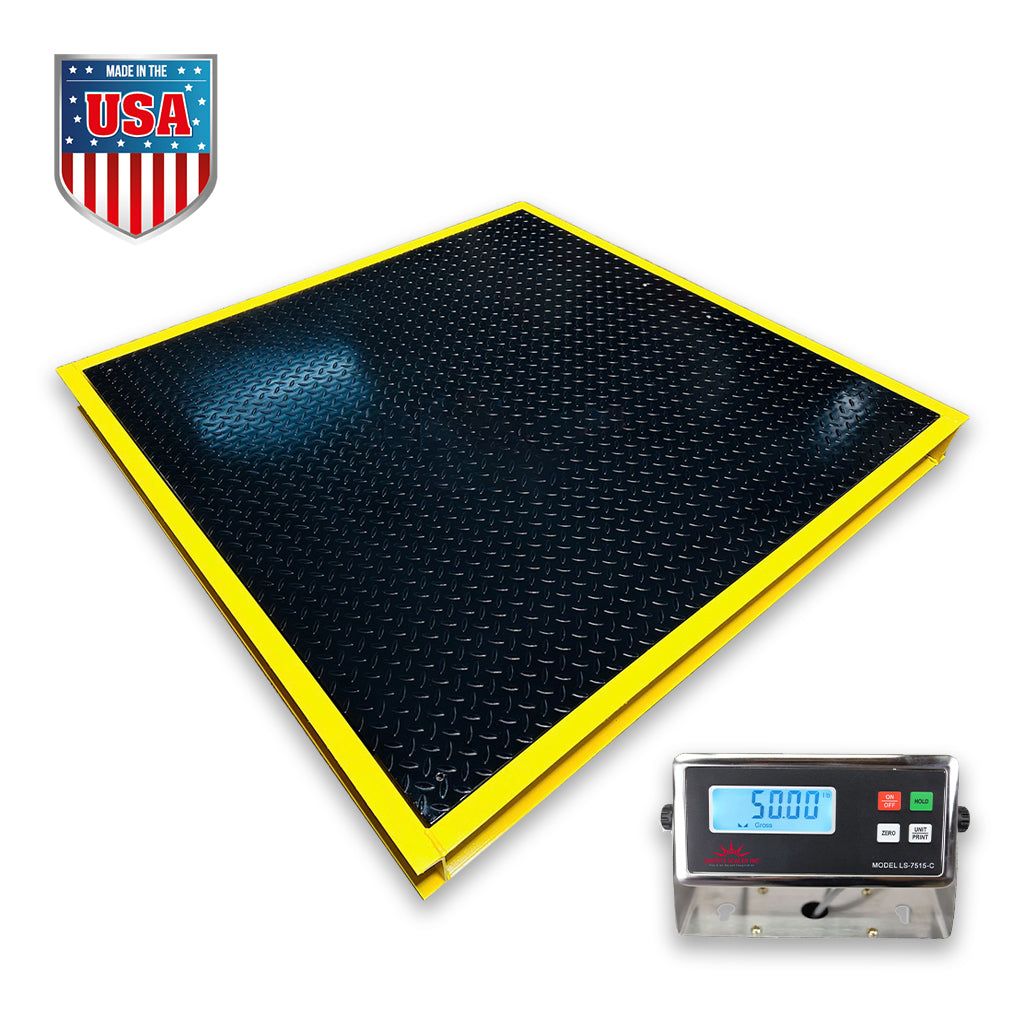

A floor scale is a type of industrial weighing scale designed to be placed directly on the ground or floor, enabling easy access for weighing large or heavy items. Key characteristics of floor scales include:

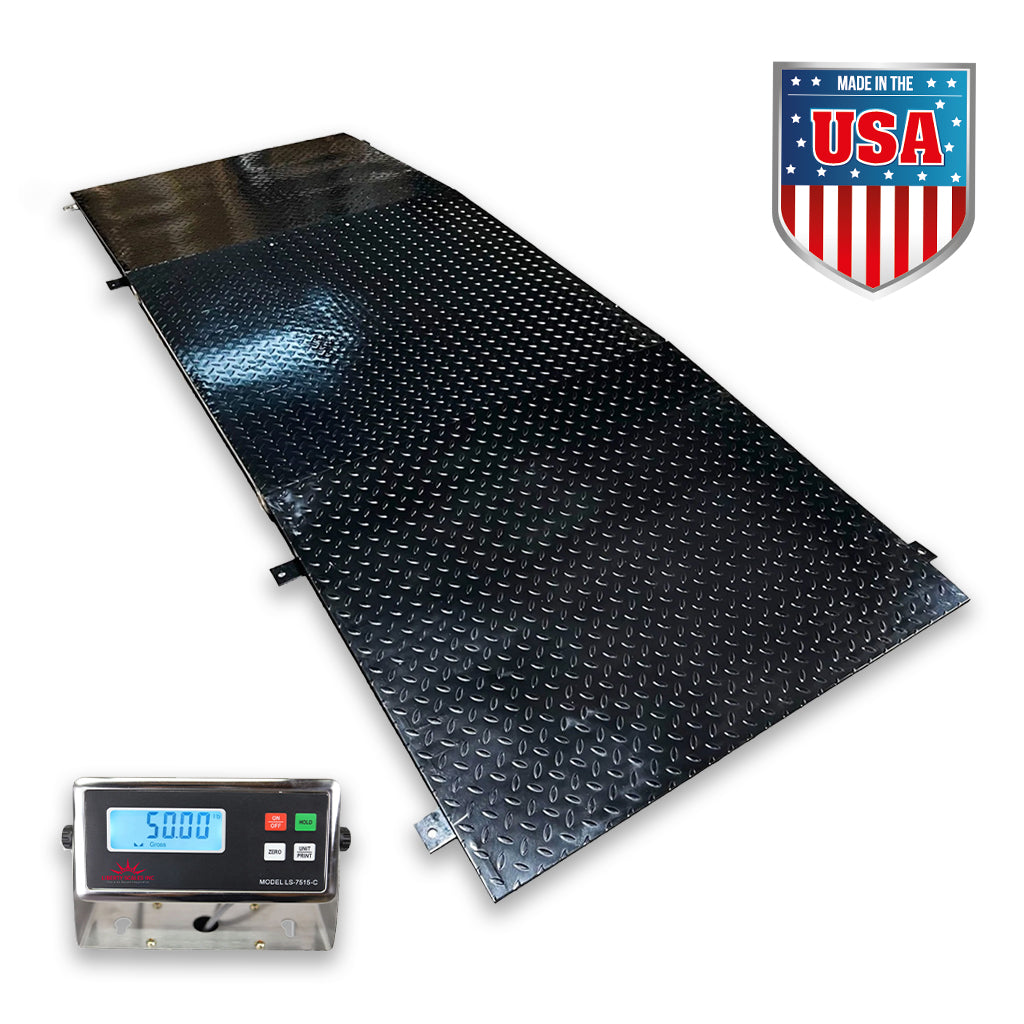

- Low Profile Design: They are typically designed with a low profile, making it easier to load and unload items, often with the help of a pallet jack or forklift.

- Heavy-Duty Construction: Floor scales are built to withstand the weight of heavy items, often constructed from robust materials like steel to ensure durability and longevity in industrial environments.

- Large Weight Capacity: These scales can handle a wide range of weights, from several hundred to several thousand pounds, making them suitable for a variety of industrial applications.

- Large Platform Size: The platform of a floor scale is relatively large to accommodate bulky items or pallets, ensuring that a variety of items can be weighed easily.

- Accuracy and Precision: Despite their large size and heavy-duty construction, floor scales are designed to deliver precise and accurate weight measurements.

- Versatility: They are used in various settings, including manufacturing, shipping, warehousing, and agricultural operations, for tasks such as inventory management, quality control, and shipping weight verification.

Floor scales are an essential tool in many industrial settings, offering a practical solution for accurately weighing heavy and large items with ease and efficiency.

What are the benefits of floor scales?

Floor scales offer high weight capacity for heavy items, ease of use with a low profile design, precise and accurate measurements, and robust durability. They are space-efficient, versatile for various industrial applications, and enhance safety with anti-slip surfaces. Additionally, many floor scales can be customized and integrated with other systems for streamlined operations.

What is the difference between a bench scale and a floor scale?

Bench scales and floor scales differ mainly in size, capacity, and intended use. Here's a concise comparison:

- Size and Capacity: Bench scales are smaller with lower weight capacity for light items, while floor scales are larger and designed for heavy loads.

- Usage: Bench scales are ideal for lighter, small-scale operations such as postal services or labs, whereas floor scales are used in industrial settings for bulky items like pallets.

- Space Requirement: Bench scales are compact and fit on benches or tabletops, saving space. Floor scales require more floor space due to their size.

- Loading Method: Items are manually placed on bench scales, while floor scales often require forklifts or pallet jacks for loading.

In summary, bench scales are smaller, suited for lighter items and require less space, ideal for manual operations. In contrast, floor scales are larger, designed for heavy-duty weighing, and are more suitable for industrial settings where larger items are weighed.

How do floor scales work?

Floor scales work by precisely measuring the weight of objects placed on them, using a combination of mechanical design and electronic components. Here's an overview of how they function:

- Load Cells: The key component of a floor scale is the load cell, a type of transducer that converts force (weight) into an electrical signal. Most floor scales have multiple load cells for better accuracy and distribution of weight.

- Weighing Platform: The object to be weighed is placed on the scale's platform. This platform is directly connected to the load cells.

- Force Application: When an object is placed on the platform, its weight applies force to the load cells.

- Strain Gauges in Load Cells: Each load cell contains strain gauges, which are small devices that change their electrical resistance when stretched or compressed. The weight on the platform causes deformation in the strain gauges.

- Electrical Signal Conversion: This deformation alters the electrical resistance in the strain gauges, creating a measurable electrical signal that corresponds to the amount of force applied.

- Signal Processing: The electrical signal from each load cell is then processed by the scale's internal circuitry. This processing translates the combined signals into a weight measurement.

- Digital Display: The calculated weight is displayed on the scale's digital or analog readout, providing the user with an accurate measurement of the object's weight.

Floor scales are designed to provide precise weight measurements for heavy and bulky items, which is essential in various industrial and commercial settings for tasks like inventory management, shipping, and compliance with safety standards.

What is the structure of a floor scale?

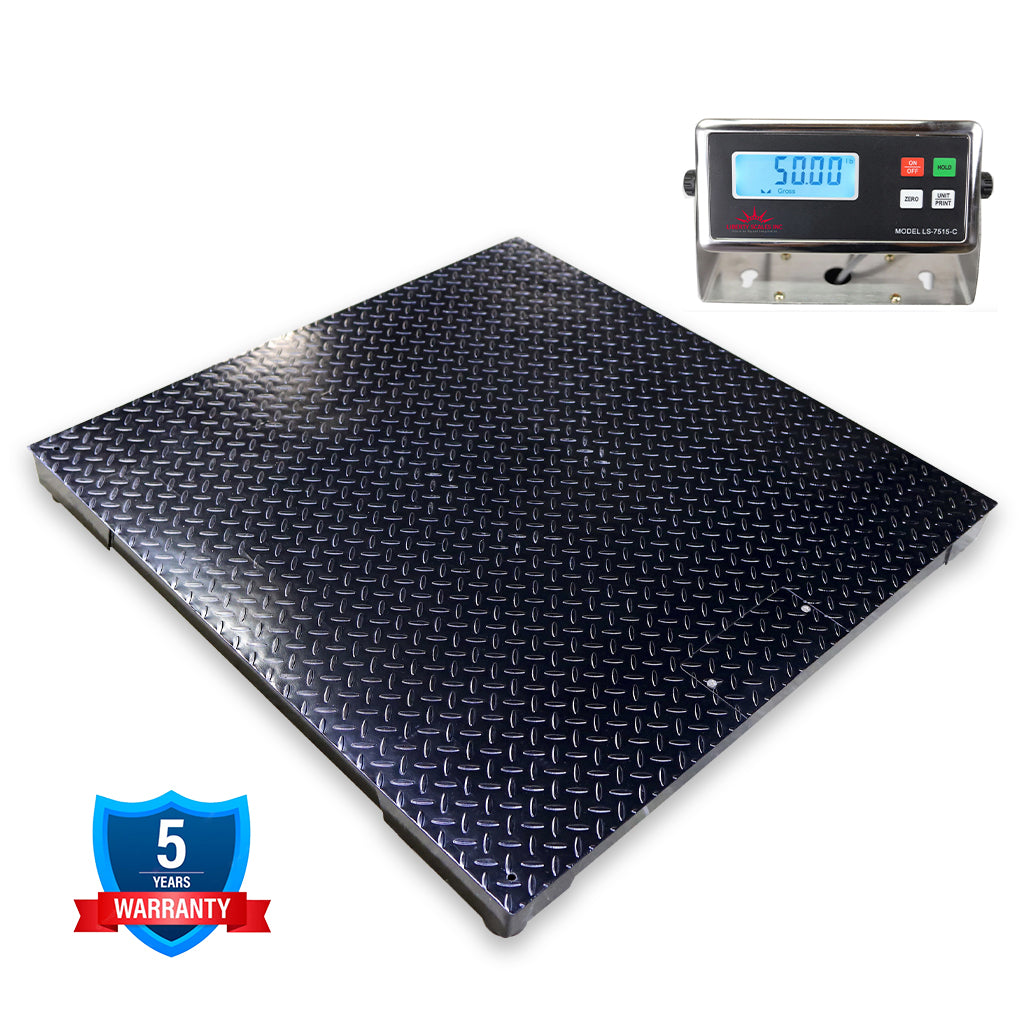

A floor scale typically consists of a durable metal platform on which items are placed for weighing, load cells that convert the weight force into an electrical signal, and a digital or analog display to show the weight. The scale is designed with a low profile for easy loading and is robust enough to withstand heavy industrial use.

What does scale measure?

Scales measure the weight or mass of an object, providing accurate readings that are essential for various applications in commerce, industry, and everyday life. They are instruments designed to measure weight, providing readings in units such as grams, kilograms, ounces, or pounds.

When is it best to use an Industrial Floor Scale?

An industrial floor scale is best used when weighing large or heavy items, particularly in industrial settings such as warehouses, manufacturing facilities, and shipping departments. It's ideal for items that are too heavy for smaller scales and require a durable, high-capacity weighing solution.

Is the Weighing Process Different for Industrial Floor Scales?

The weighing process for industrial floor scales is generally similar to other scales but adapted for heavy-duty use. Items are placed on a large platform, and the scale provides precise weight measurements, suitable for large, bulky, or heavy items typical in industrial environments.

What should I consider before buying an Industrial Floor Scale?

When purchasing an industrial floor scale, consider the following factors:

- Weight Capacity: Ensure the scale can handle the maximum weight you plan to measure.

- Size and Footprint: Choose a scale with a platform size that fits your space and can accommodate the items you'll weigh.

- Accuracy: Consider the precision you need for your weighing tasks.

- Durability and Material: Look for robust construction suitable for your work environment.

- Ease of Use: Check for user-friendly features like a readable display and simple controls.

- Calibration and Maintenance: Understand the calibration process and maintenance requirements.

- Legal for Trade: If using the scale for commercial transactions, it must be certified as 'legal for trade'.

- Cost: Balance between features and your budget.

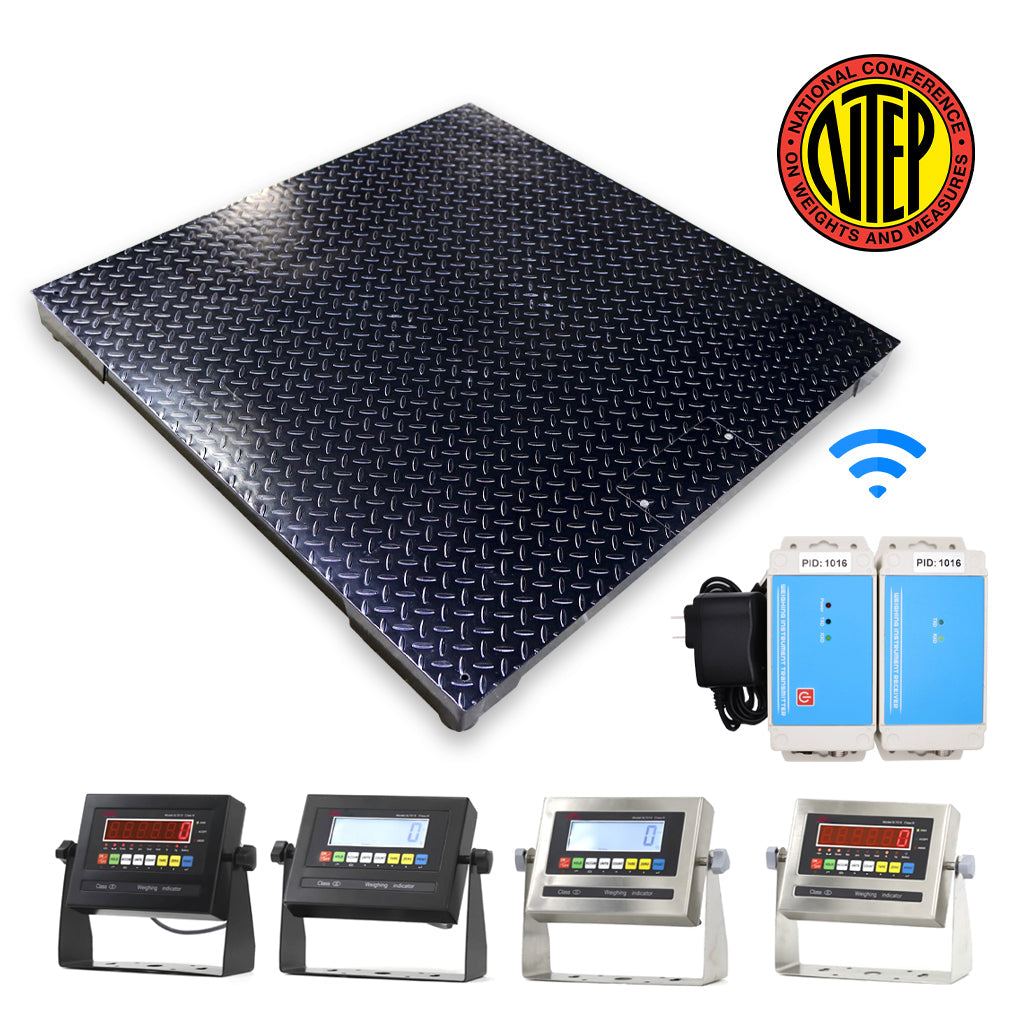

- Additional Features: Consider extra features like connectivity options or integration capabilities with other systems.

- Warranty and Support: Check the warranty and customer support services provided.

What Industry Benefits most from Heavy-Duty Floor Scales?

The Automobile industry greatly benefits from heavy-duty floor scales, especially truck scales, to ensure vehicles comply with legal weight limits for safe navigation and road protection. The Pharmaceutical industry also relies heavily on pallet scales for precise weighing, crucial in determining accurate chemical compositions and medical dosages.

What type of Industrial Floor Scales do you offer?

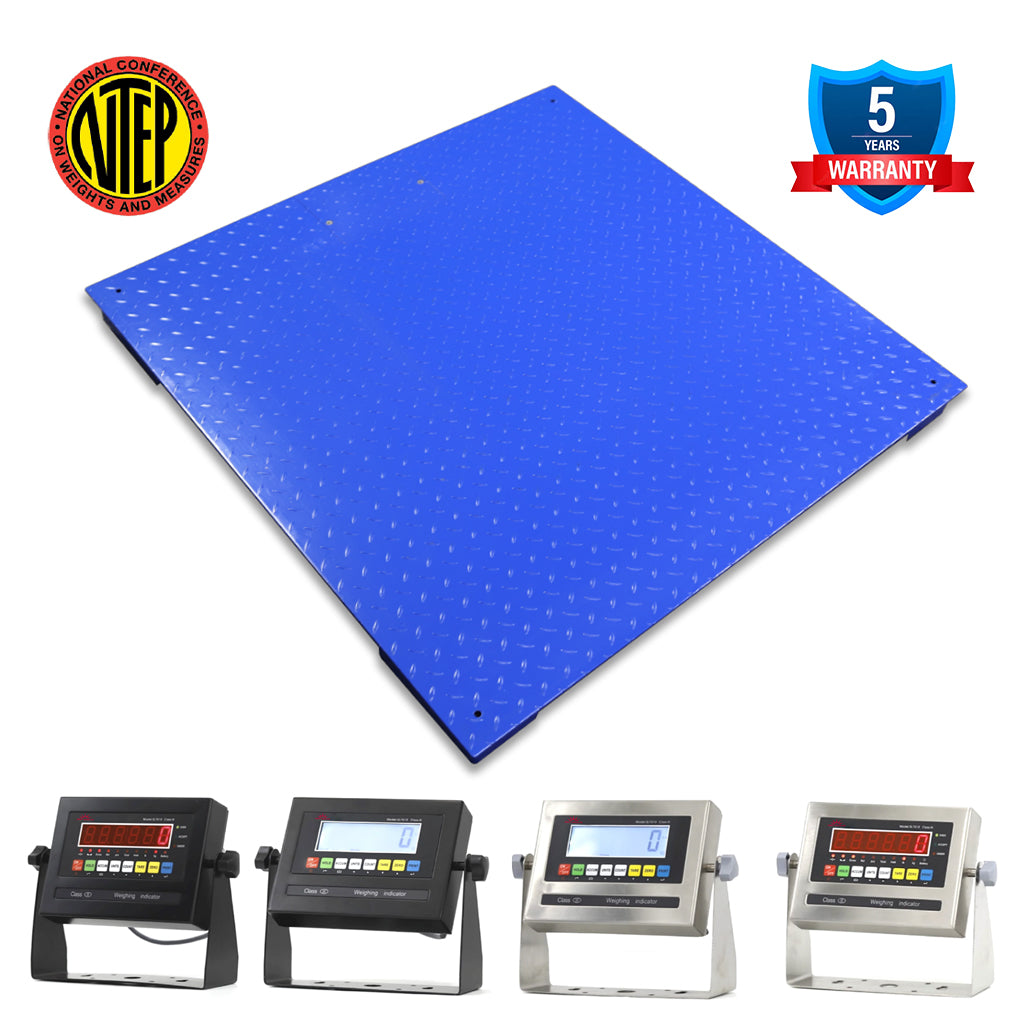

We offer many types of floor scales. Our wide range ensures you can find solutions suitable to your needs. Here is a list of our main varieties:

- Heavy-Duty Floor Scales: Ideal for weighing large items.

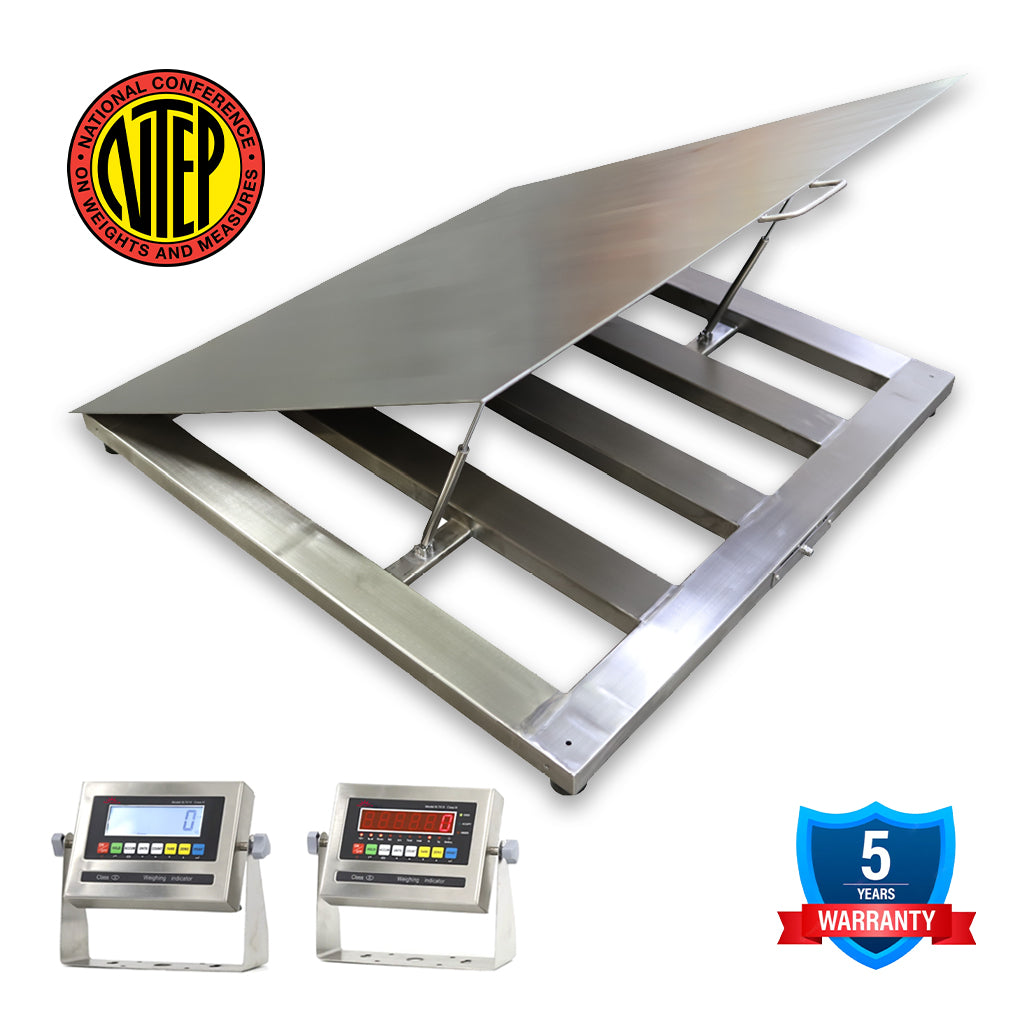

- Stainless Steel Scales: Durable and long-lasting.

- Pallet Size and Smaller Scales: Versatile for various applications.

- Scales with or without Ramps: For easy loading and unloading.

- Warehouse Floor Scales: Can weigh up to 10,000 pounds.

- Scales with Printer and Scoreboard: For immediate data recording.

- Heavy-Duty Weigh Bar Beams: With a capacity of up to 20,000 pounds.

- Customizable Stainless Steel Scales: Build your own with ramps and other features.

- Legal-for-Trade Bench Scales: Suitable for commercial transactions.

Do you have Free Shipping?

We offer various payment options, including credit cards, PayPal, and Amazon Pay. For Amazon Prime account holders, free shipping is available on eligible orders. Customers without an Amazon Prime account will incur a shipping fee.

What is included in the Shipment?

The contents of your delivery will vary based on the specific scale you purchase. For scales with special features like a printer or scoreboard, these will be included in the shipment. If you choose our 'Build Your Own' floor scale kit, it will contain the specific features and components you selected during the purchase process.